Before - Pretty Basic M4, Aimpoint is a very new addition

After, along with some other upgrades

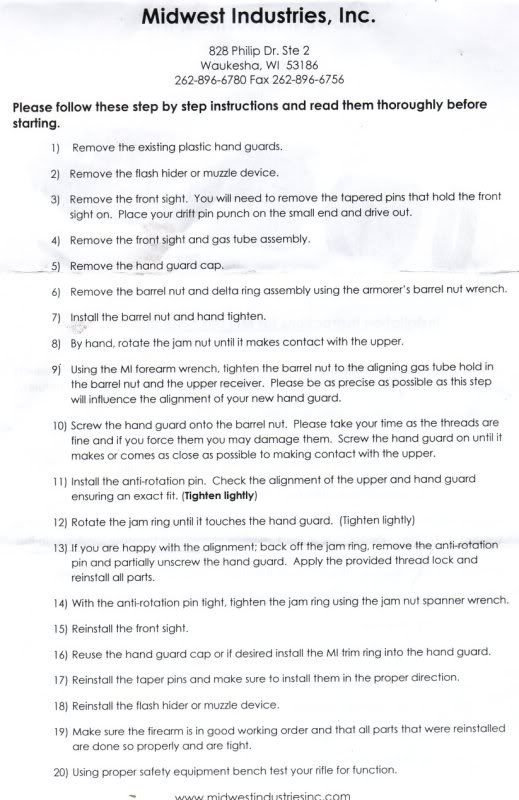

Instruction Sheet

Midwest Industries (MI) is now making one-piece float tubes, in addition to their two-piece, no-gunsmithing, float tubes. The one-piece tubes use an aluminum barrel nut rather than the steel G.I.-type barrel nut, which saves some weight. The handguard itself requires less material than a two-piece float tube, saving a little more weight. The one-piece tubes are also cheaper than the two-piece tubes, at about $155 vs.$228 for the 12" versions.

I was afraid that if I bought one of those $300+ handguards then I’d be afraid to really use it. That, and I’m too cheap to drop that kind of cash, when I can get almost the same thing for about half the price. I went with the rifle-length handguard on a 16” barrel because the rail I had bolted to the bottom of the plastic M4 handguard was proving to be too short. I was pleasantly surprised with the MI Low-Profile rear sight, so I gave MI a shot with the railed float tube.

I’m liking the rifle-length handguard on the carbine upper. I think I have more muzzle control with the vertical grip mounted farther out from the receiver (like Kyle Lamb says). The extra length gives more freedom in bracing the rifle against hard cover without the barrel touching anything. It gives a longer sight radius too, obviously. It was worth the extra 2 and half ounces (15.4oz., rather than 12.9oz.), over the 10” handguard, I think. Weight of the 12” Daniel Defense Lite tube (currently $332 at Bravo Company), by the way, is listed at 14oz. The 12” Lightweight YHM tube (currently $139.95 at Bravo Company) weighs 14.75oz. Price of the MI T12 at Bravo Company is currently $155, to give you a little bit of a comparison.

The handguard comes with the required Allen wrench for installation, a small vial of threadlocker, and a decent instruction sheet. It doesn’t come with a spanner wrench for the locknut. I might have bought a spanner wrench, but there wasn’t any available when I bought the handguard, so I just put the blade of a screwdriver in the slot of the locknut and tapped it with a hammer. With the help of the threadlocker, the locknut is holding tight, and somewhat to my surprise, the screwdriver didn’t leave a mark on the ring.

Installation on an already assembled upper will require removing any muzzle device present, the gas tube, the front sight tower or gasblock, and finally the delta ring assembly or barrel nut.

Tools required:

1/16” pin punch for the gas tube roll pin

3/32” pin punch for the front sight tower pins (if present)

Hammer – claw hammer at minimum, those front sight tower pins can be tough to start moving

Grease – for removing and reinstalling front sight tower or gas block, and rust preventive on the barrel and steel parts covered by the tube

Degreaser – for cleaning MI barrel nut, lock nut, and anti-rotation screw before applying threadlocker

½” wrench, or large crescent wrench for muzzle device (if present)

Some sort of barrel nut wrench (should be under $25)

Vise

Upper receiver block (Model 1 Sales action block is about $35)

Torque wrench for reassembly (31 foot-pounds minimum, up to 80 foot-pounds is desirable to break-in the threads of the barrel nut, per the TM)

MI lock nut spanner, or hammer and flat blade screwdriver

I removed the sling swivel from the front sight tower, and shaved it into a low-profile gas block which required more tools – drill and 1/8” drill bit, Dremel rotary tool, cut-off wheel, stone grinding bit, files, and black BBQ spray paint. I don't trust the set-screw type gas blocks, and didn’t want to spend $50+ for a clamp-on gas block.

Don’t forget to order another crush washer for the muzzle device if you want/need to use one. They aren’t reusable (yeah, I tried; not enough friction to hold the flash hider on). I think the peel washers are reusable, but I don’t like them, so I’m really not sure.

Anti-Rotation Pin Screws Into The Tube, Locking It In Place In Relation To The Barrel Nut

The only issue that I’ve had with fitting things to the handguard was with the Vltor Scout Light mount. The scout mount fit, but the rails on the handguard seem to be oversized, and the mount would not clamp the flashlight solidly in place without a little shim that I cut from a soda can. The scout mount worked fine on the rail of a flattop upper, so it’s not the Vltor mount that’s the problem.

The Yankee Hill front sight, MI sling mount, Larue QD scope mount, and Tangodown Quick-Detach Vertical Foregrip all fit fine.

The only real complaint I have about the MI handguard, is the finish. MI advertises that all their stuff is hard anodized, but I’m finding that it scratches really easily. I was finding scratches before I even really used the rifle. Not a big deal, but it might be if you really want a pretty “safe queen.” The matte black coating on the Larue Beverage Entry Tool has held up to opening many “adult beverages,” so if you want a tube with a tough finish, you might want to give a Larue tube a try.

Non-spec rails aside, the handguard is okay. It works with many accessories, but not all of them. My newer YHM Lightweight hanguard seems to be made to the proper spec, and has worked with everything I've tried on it so far.

EDIT, 6/30/2010: It seems that MI customer service is pretty aweful. Check MarylandShooter's site for more details.

EDIT, 9/28/2010: When I went to check the locking ring on the handguard with the YHM spanner wrench, the nut was pretty loose. It might have been okay, but the wrench does seem to allow more torque on the nut.

3 comments:

Does the MI T series barrel nut require a proprietary barrel nut wrench or will the standard wrench fit it? I noticed that the MI website says that you will need the MI wrench.

I used a PRI barrel nut wrench, which is a seriously sturdy piece, by the way. It's the same type that you'd use to remove the G.I. barrel nut and delta ring assembly.

The MI spanner wrench for the locknut may not be a horrible idea, but like I said (or rather wrote), a flatblade screwdriver and a couple taps with a hammer did the job.

Thanks for posting up this write up! I, like you purchased the MI rail without the spanner wrench. I was going to order one and wait, but after I read that you can use a screwdriver and a hammer I am going to take your route and save $20 bucks. Thanks for the tip!

Post a Comment