|

| YHM Rifle-Length Lightweight Tube on my RRA 16" 9mm Upper w/YHM wrench |

|

| Lots of holes, and the rails are milled out to cut weight. |

I tried the Vltor light mount on the YHM handguard, and it does indeed work properly without the silly shim. Everything else seems to fit fine on the YHM also.

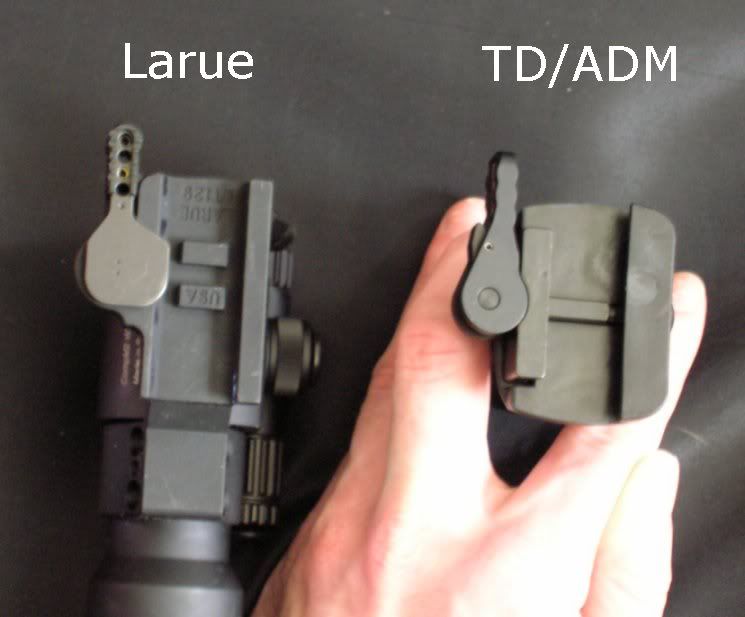

I was afraid that the indexing/recoil lug on Larue mounts would not work with the milled-out rails, but the lug does still engage some of the rails on the lightweight tube. In .233Rem/5.56mm, there’s not enough recoil for the lug of the Larue mounts to really be necessary as a recoil lug.

|

| Larue mount lugs just barely engages the milled-out rails |

The YHM tool can not be used with a torque wrench, and would require a very large diameter pipe to use as a cheater bar for more leverage.

The YHM wrench works fine on the Midwest Industries lock-ring also, by the way.

Once I got the barrel nut/delta ring assembly, and front sight tower off the RRA upper, installing the new handguard was simple. It installs just like the MI handguard, except that it has two indexing screws, at 3 and 9 o’clock, instead of just one at 6 o’clock like the MI handguard. The barrel nuts of the YHM lightweight and MI T-Series handguards are nearly identical. The indexing screws for the YHM are slotted, where the MI handguard has allen-head socket screws. There were no tools or threadlocker included with the YHM handguard. The rail covers shown in some of my pictures were not included either.

The only minor issue I had was aligning the barrel nut so that the top rail of the handguard matched up with the rail on the upper. The 9mm upper is blow-back operated, and had no gas tube hole to use to align with the hole the barrel nut. If you are picky, it may take 2 or 3 tries to get the rails to line up just right, but the same is really true of most railed handguards.

The lightweight YHM does not give the full-length top rail effect. Although, as you can see in the photo below, the MI T-Series handguards don’t have a slot over the lockring anyway, so it really doesn’t make that much difference.

|

| YHM Lightweight on Top, MI T-12 on Bottom |

The YHM lightweight handguards have holes at the front end for screwing in YHM’s sling mount. These holes are NOT QD sling swivel sockets for the swivels that release with a push-button. I believe that the top and bottom holes are for the YHM endcaps, and the holes on either side are for the YHM screw-in sling swivel studs, but don’t use either an endcap or a sling swivels, so I’m not really sure. Sling mounts and endcaps are sold separately.

I’m quite happy with the YHM Lightweight handguard. Depending on how the Spike’s Tactical slim handguard turns out, there’s a good chance that I may buy another YHM lightweight for my LMT 10.5” upper. I have no plans to buy another MI handguard until they start cutting the rails to proper Picatinny specifications.

EDIT 1/13/12: I liked the 1st one so much, I got another for my Spike's 5.45mm upper. When I decided to put a free-float, railed handguard on my SBR/pistol upper, I bought a mid-length lightweight handguard for that. Yes, the Daniel Defense Lite handguard is slimmer, but I have not found the width of the YHM handguards to be a problem, and the YHM tubes are about a third the price of the DD Lite. For me, it's an easy win for YHM. Have not found anything yet that won't fit the YHM rails.

The Spike's slim handguard that I mentioned, comes with rail covers, and I think has QD sling sockets and an included sling swivel, but costs nearly what the DD Lite does. I was tempted, but ultimately decided to skip it.

The free-float tubes with bolt-on rails have started to become popular. My issue with these, is that when you start to bolt on more rail sections, they start to become heavier and more expensive than a quad rail handguard, while still lacking the versatility. I also think they usually look sort of goofy, but maybe that's just me.

If you are looking for a YHM Lightweight handguard, Primary Arms has the cheapest prices that I have seen, so far, and service from them has been excellent.

Related Links:

Yankee Hill Machine Home Page

No comments:

Post a Comment